In order to thrive in times of economic turbulence and supply chain disruptions, companies should be built from the top down, with quality and efficiency being of the utmost importance. Common problems like manufacturing faults and shipping delays eventually harm the relationship with the clients or consumers and can jeopardize a whole enterprise.

In the constant pursuit of operational excellence, organizations around the world are rapidly shifting towards the principles of the Lean Six Sigma black belt. They are doing so not only to streamline the processes but also to eliminate any kind of waste and increase the overall productivity of the Lean Six Sigma Black Belt certification.

It goes without saying that this is one of the most sought-after certifications in the world of improvement. It is due to the advantages of having a fully trained Lean Six Sigma black belt within your organization.

Lean Six Sigma Green Belt Vs. Black Belt

Lean Six Sigma is basically something that integrates the lean management approach to team leadership, waste control, and quality control with Six Sigma principles focused on decreasing defects via tactical approaches and scientific reasoning. The green belt accreditation signifies the grasp of basic LSS principles, including procedures, tools, and methodologies to streamline services and productions. Quite often, this certificate is a requirement for gaining a black belt.

- The green data basically concentrates on the local projects, with the conjunction of the black belt accumulating and analyzing the data. They introduce the procedure of enhancement depending on the obstacles based on their prevalent procedures.

- Black belts, who are certified, are the experts in transforming their company into a leaner and more efficient operation. These are typically the team leaders who are working cross-functionally.

The efforts that they put forward directly impact customer satisfaction, professional growth, and financial gain. They are responsible for the organization’s refining, evaluating, and investing processes.

If we look at it from someone outside the field, the knowledge of black and green belts may seem relatively similar. However, folks who are the black belts are actually the individuals who decide on courses of action and team meetings when there is a defect. Green belts are the folks who take roles in analyzing weaknesses, considering team dynamics, and leading data collection.

How are the principles of the Lean Six Sigma Black Belt integrated?

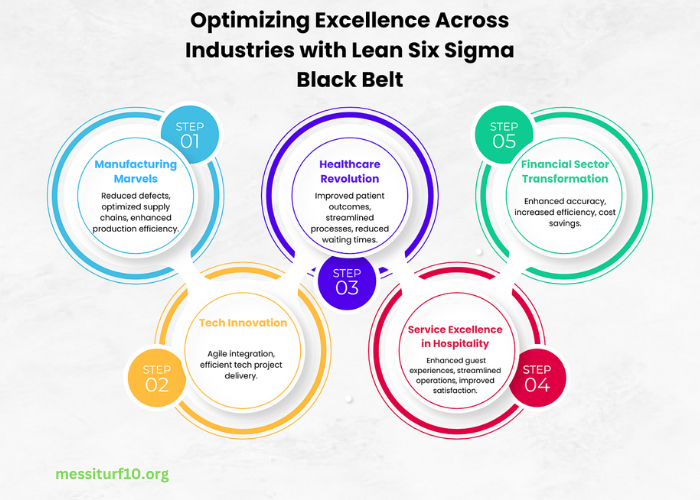

The course of Lean Six Sigma black belt takes delegates from a standing start and moves onto the right way through the improvement methodology of Lean Six Sigma. The core green belts are taught with the addition of even better change capability in the form of both leadership and technical skills needed to deliver a successful change. Here is how the Lean Six Sigma belt principles have integrated so far:

-

Revolution in Healthcare

Patient outcomes are improved by Lean Six Sigma black belt specialists in the accuracy and efficiency-driven healthcare industry. Credentialed people make a noticeable difference in the quality of care by expediting administrative processes and cutting down on wait times.

-

Innovation in technology

Though efficiency is equally vital, innovation is what drives the tech business. Over the years, agile development techniques have included Lean Six Sigma Black Belt principles to ensure that IT projects are completed on time and efficiently.

-

Precision in manufacturing

Manufacturing firms were the first to implement Lean Six Sigma techniques. Certified Black Belts are essential for streamlining the supply chain and cutting down on manufacturing faults in line with production.

-

Economical transformation

Accuracy and efficiency are critical in economics. Over time, employees who have earned a Lean Six Sigma Black Belt certification contribute to systemic changes in finance, insurance, and banking that eventually raise customer satisfaction and save costs.

-

Change in the hospitality industry.

Accuracy and efficiency are critical in economics. Over time, employees who have earned a Lean Six Sigma Black Belt certification contribute to systemic changes in finance, insurance, and banking that eventually raise customer satisfaction and save costs.

Benefits of Lean Sigma Six Black Belts

Whenever there are any sort of issues with the processes and procedures, it is the time when the lean sigma black belt and green belt come in. Here are some of the benefits of the lean sigma six black belt course:

- LSS Black Belt specialists are the experts in evaluating and analyzing current tactics and putting improvements into practice to decrease waste, boost efficiency, and improve production when process difficulties develop in their organizations. Essentially, the LSS method’s objective is to reduce production waste by integrating the technologies into an organization’s workflow.

- The Black Belt represents a professional’s aptitude for implementing improvement procedures at work. Black Belts understand the fundamentals of their company. They are also able to identify and evaluate barriers and pose the appropriate queries.

They are often called “critical thinkers” because they are always thinking about cause and consequence. Whether it be a problem with subpar goods, delayed deliveries, or medical blunders, Black Belts identifies the flaws in the methods currently employed in their company.

- Black Belts are characterized as skilled leaders with excellent communication and project management skills because they are passionate about what they do and understand the needs of their customers.

Employing managers will be aware to look for Black Belts in their hiring processes because of their technical skills and natural ability to lead and collaborate with others while always keeping success in mind.

- Students in a Black Belt training are prepared to choose from a matrix of four project types: the company’s bottom line, Six Sigma propagation, internal customers, and external customers. When learners work with a nonprofit or employer, they apply the concepts and tools they have acquired to carry out an appropriate project.

Wrapping up

The use of Lean Six Sigma Black Belt concepts across a range of sectors attests to the adaptability and potency of these techniques. Employee certification not only equips workers with the know-how to plan for future expansion, but it also gives businesses the edge they need to succeed in the rapidly changing business environment.